Introduction

The Dakota/Durango platform, designed and sold by Chrysler from 1997-2004, is the third generation of this mid-sized truck. Adopting a modern appearance, in stark contrast to the previous box design, this truck is still considered to be attractive. The chassis, body and interior have shown themselves to be durable, and this truck has a strong following, making it a potential classic as the first trucks will soon reach the 20 year mark.

Despite the availability of the 5.9, 250 hp “Magnum” engine with an updated 46re overdrive transmission from 1998-2003, the truck suffered serious weaknesses in the drivetrain throughout the 7 year run. The chassis was heavy, tipping the scales at nearly 4,000 lbs, and emissions requirements were tight, requiring a lower compression, hypereutectic pistons to prevent

blow-by. Cylinder heads in the “Magnum” were also known to crack between the exhaust valves, resulting in un-repairable damage. In addition, the aftermarket has never embraced the Mopar, leaving sales of performance products at only 3% of total sales. This meant the options were very limited.

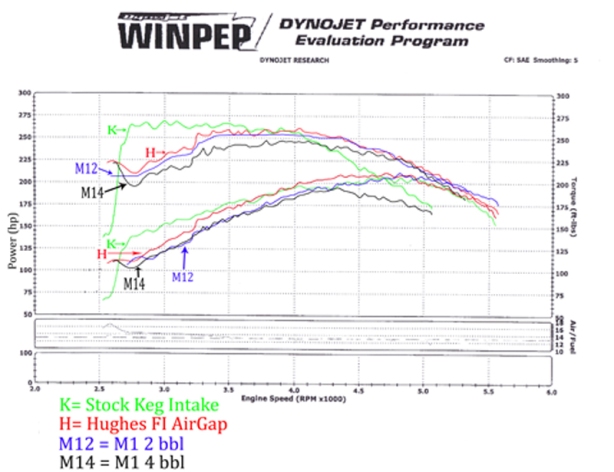

The horsepower motor from the 5.9 Magnum line has been modified many times by enthusiasts. Typically beginning with cold air intake, dual exhaust, SCT tuner, throttle body, and intake. The cost is in the range of $1200-1500, depending on throttle body choice and exhaust. This will quickly expose the weakness of the heads, which flow about 210 cfm above .400 lift. Head swap and roller rockers usually come next, at a cost of $1075 each for updated stock heads (iron) with stainless valves and springs of your choice (not including shipping). A cam will cost another $200-$300 resulting in about 320 RWHP. While the stock bottom end can support in excess of 500 hp, getting there will require new pistons or rotating assembly, or forced induction. But the bottom end will ultimately be consumed by heat. Prices are exponential with quality, of course. Oh, and don’t forget the weakness of the 46RE transmission. It won’t be crying tears of joy above 400 hp.

The Problem

After purchasing a 1999 Dakota R/T, 160k miles, to use as a daily driven shop truck, it was quickly determined that the heads were damaged, of course. After the motor was removed and disassembled, it was determined that a rebuild and new heads would be required. Choices, stock motor roughly $3000 with new hoses and accessories, or higher performance in the 300 hp range for roughly $5000. Ouch.

Then we came across an article “World’s easiest 5.3 swap”, on a discussion forum. Turns out, the LS-style drivetrain shares very similar dimensions to the Magnum drivetrain.

The Goals

1) Insert a modern drivetrain into this soon to be classic truck

2) OEM appearance

3) OEM durability and drivability

4) Minimal modifications

The Solution

A call to Shawn, at RetroLSX resulted in the purchase of an LY6/6L90 combo with pedal, ECU, accessories, harness, and exhaust flanges. A call to VanPelt Sales resulted in a plastic mock-up long block of the LS1, and a call to Jared at Current Performance resulted in confirmation that integrating the wiring into the Dakota harness was possible.

After a couple of days and a number of adapter plate designs, the LS mock-up sat in the chassis with good drivetrain alignment and no clearance issues. Another couple of days allowed for the placement of the 6L90 transmission. Modifications for the drivetrain placement included a 9″ X 3″ cut in the middle crossmember for oil pan clearance, and minor notching of both stock motor perches. The crossmember modification was reinforced with 2 1/4 inch mild steel tubing welded in. A spacer was required to place the transmission in the existing crossmember.

Retaining the existing motor perches, as opposed to cutting them flush and welding new mounts, retained the existing triangulation of the front suspension, using the engine block as the compression component during suspension travel. Stock truck manifolds from the LY6 cleared with mild grinding, and placed the exhaust exit in good position. Front accessories were retained from the LY6, with the power steering pump attaching to the stock rack and pinion steering assembly. The air conditioner was relocated using a kit from Current Performance. An electric fan from a Ford Taurus was attached directly to the stock radiator, and hoses were fabricated from off-the-shelf parts from the local NAPA store.

Dependable Driveshaft provided a 5″ aluminum unit with the correct dimensions, and the truck was moved to Current Performance, where the wiring harness was integrated into the existing distribution block using correctly labeled circuits.

Fuel system was fabricated out of OEM nylon tubing, 3/8 inch, with a Walbro 255 HP pump in the stock tank. A Corvette filter/regulator was used just forward of the tank on the frame rail, with a 5/16 rubber return line.

A GMC Sierra shifter cable was attached to the column-mounted shifter with minimal modifications, and the drive-by-wire brake pedal was converted to a “franken-pedal”, using half Dodge, half GM structures.

A final weakness was corrected using custom adapter plate and spacers to locate a pair of front rotors to the rear, completing a rear-disc conversion for better stopping power.

The trans tunnel was repaired, and a custom fiberglass console was fashioned to provide for deeper cup holders, an improvement as well.

The Results

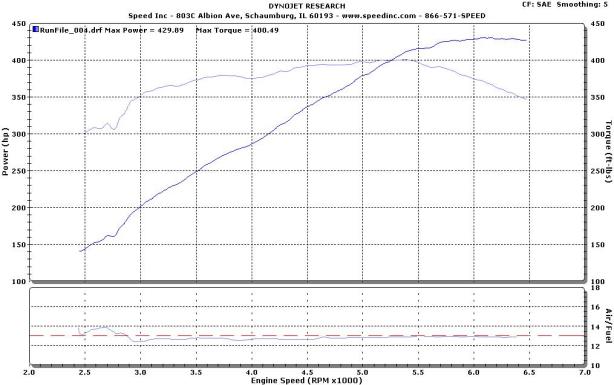

With the addition of an Airraid cold air intake, and 2 1/2 inch dynomax dual exhaust, the motor is probably putting out a healthy 370 HP/390 TQ at the flywheel. Retaining the VVT, at least for now, will hopefully provide more useable torque. The 6 speed transmission shifts flawlessly, and the drivability is excellent. The OEM 3.92 gear ratio might be a little aggressive, and fuel mileage may be improved somewhat with a ratio of 3.60-3.70, but initial numbers show a 0-60 time of 5.8 seconds with a fuel mileage of 14 mpg. 10-70 and 30-70 performance is much improved over the lazy magnum feel, and sound levels are comfortable.